| Other featured projects

Highway Capacity Manual (HCM) Website Integrated Transportation Information System (ITIS) Workshop Demonstration Projects (DP) DP-105 Advanced Transportation Management Technologies DP-111 ITS/CVO Technology Truck DP-112 Red Light Running Campaign DP-115 Probabilistic Life Cycle Cost Analysis in Pavement Design Test and Evaluation Projects (TE) Application Projects (AP) |

| |  Project: TE-29 Project: TE-29Retroreflectivity Contact: Drivers and highway department personnel have long recognized that good pavement markings and legible road signs are essential for efficient traffic flow, driving comfort, and highway safety. This is especially true at night and during inclement weather. One technology which has done much to improve the visibility of pavement markings and road signs is that of retroreflective paints and coatings. However, over time, retroreflective paints degrade due to the effects of traffic and weather. It is not always easy to determine the best time to replace the retroreflective pavement markings. If replaced too soon, maintenance costs are increased. If replaced too late, safety and driving comfort are compromised. Project TE-29 was implemented to solve this problem by giving highway departments some state-of-the-art measurement tools and techniques that they can use to scientifically evaluate the actual condition of highway signs and pavement markings, in place, along the highways. Highway department personnel can now efficiently monitor the wear and condition of

retroreflective markings and feel confident that they are maintaining them for optimum

safety, performance, and economy. What is "Retroreflectivity"?Retroreflectivity (Reh-troh re-flec-Tiv-i-ty) is the optical equivalent of the phrase "right back at you!" Many retroreflective highway signs and pavement markings use special sign sheeting and pavement marking materials that send a large portion of the light from your car's headlamps straight back along the same path it came from. This has the effect of making retroreflective objects appear to shine much brighter than otherwise identical ones without the retroreflective materials. What does this mean to the driver? It means that signs can be clearly seen from much greater distances at night, giving drivers more time to plan lane changes and exits. It also means that road markings appear brighter and can be seen more clearly. All this is making our highways much easier and safer to navigate. Retroreflective Paint

Instead of simply scattering light, as normal paint pigments do, retroreflective paints with glass beads turn the light around and send a large portion of it back in the same direction it came from. This has the effect of making retroreflectively painted objects appear much brighter than otherwise identical ones painted with normal pigments. However, over time, traffic and the weather gradually wear down the retroreflective paint by knocking loose or scratching the tiny glass beads. When this occurs, the markings will lose their nighttime visibility or brightness and need to be replaced. In the past, it was not always easy to determine the best time to replace the retroreflective markings. If replaced too soon, maintenace costs are increased. If replaced too late, safety and driving comfort are impacted. The TE-29 Project is helping solve this problem. Retroreflectivity Measurement ToolsDrivers know that legible road signs are essential for driving comfort and highway safety, especially at night and during bad weather. Retroreflective sign sheeting technology has done much to improve the visibility of road signs. However, over time, retroreflective sign sheets degrade due to the effects of traffic and weather. It is not always easy for highway department personnel to determine the best time to replace road signs. In the past, subjective evaluation techniques have proven inefficient. If the signs are replaced or reconditioned too soon, maintenance costs are needlessly increased. If replaced too late, safety and driving comfort may be compromised. Project TE-29 was implemented to help solve this problem by demonstrating state-of-the-art measurement tools and by establishing standardized techniques and metrics that can be used to scientifically evaluate the actual condition of highway signs and pavement markings, in place, along the highways. Three key tools being developed and evaluated in the TE-29 Project are:

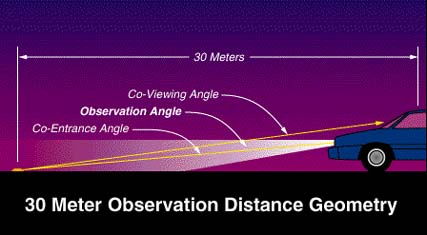

Highway department personnel adopting these new tools and techniques can feel confident that they are maintaining their retroreflective markings for optimum safety, performance, and economy. Mobile Sign Retroreflectometer VanThe Mobile Sign Retroreflectometer Van will be used in the field to measure and evaluate the condition of the retroreflective sheetings used on highway signs. The van uses a calibrated strobe lamp, mounted on top, to bounce light off highway signs. The returned light is processed by computer to account for angle, distance, and other parameters, then measured and compared to standards. The Mobile Sign Retroreflectometer Van is being designed and constructed through an interagency agreement with the Naval Research Laboratory (NRL) located in South West Washington, D.C. Under the Interagency Agreement, NRL will develop plans and specifications, build one Mobile Sign Retroreflectometer Van system, train Federal Highway Administration personnel to operate the system, and showcase the system. Mobile Pavement Marking Retroreflectometer VanThe Mobile Pavement Marking Retroreflectometer Van was developed to efficiently measure the condition of the retroreflective pavement markings. In the past, this job had to be done using hand-held devices, making the process of taking sufficient measurements labor-intensive and costly. The Mobile Pavement Marking Retroreflectometer Van has the ability to take many continuous retroreflectance readings while driving down the road at highway speeds. It is this ability to quickly handle vast amounts of data that will help highway department personnel determine when pavement markings need to be replaced, and to assure that the retroreflectance value of the pavement markings are meeting standards. The Pavement Marking Retroreflectometer Van employs standardized "30-meter Observation Distance Geometry". Hand-held Pavement Marking RetroreflectometerIn addition to the Mobile Pavement Marking Retroreflectometer Van, the Federal Highway Administration is promoting lower-cost Hand-held Pavement Marking Retroreflectometers. These lower-cost versions can be widely deployed in the field to spot-check the condition of selected retroreflective roadway markings. As with the van-mounted version, the Hand-held Pavement Marking Retroreflectometers also employ standardized "30-meter Observation Distance Geometry". Pavement Marking 30-meter Observation Distance Geometry

30-meter Observation Distance GeometryAll pavement marking retroreflectometers being promoted by the Federal Highway Administration employ 30-meter Observation Distance Geometry. This standard was selected because it closely conforms to what an average passenger automobile driver sees when viewing 30 meters ahead of the vehicle at night. This standard observation geometry is likely to be adopted world-wide, and has already been adopted in Europe by the European Committee on Normalization. Technical Purchasing ConsiderationsWhat to look for when purchasing a pavement marking retroreflectometer:

For a brief overview of retroreflectivity and TE-29, download the Retroreflectivity PowerPoint presentation. |